LP2’s optimal engraving distance is 110±1mm (i.e. 109-111mm). Too close or too far will result in uneven results when you engrave a large-ish area, say over 65mm x 65mm. If you are unsure about it, test on some scrap material after setting the engraving distance.

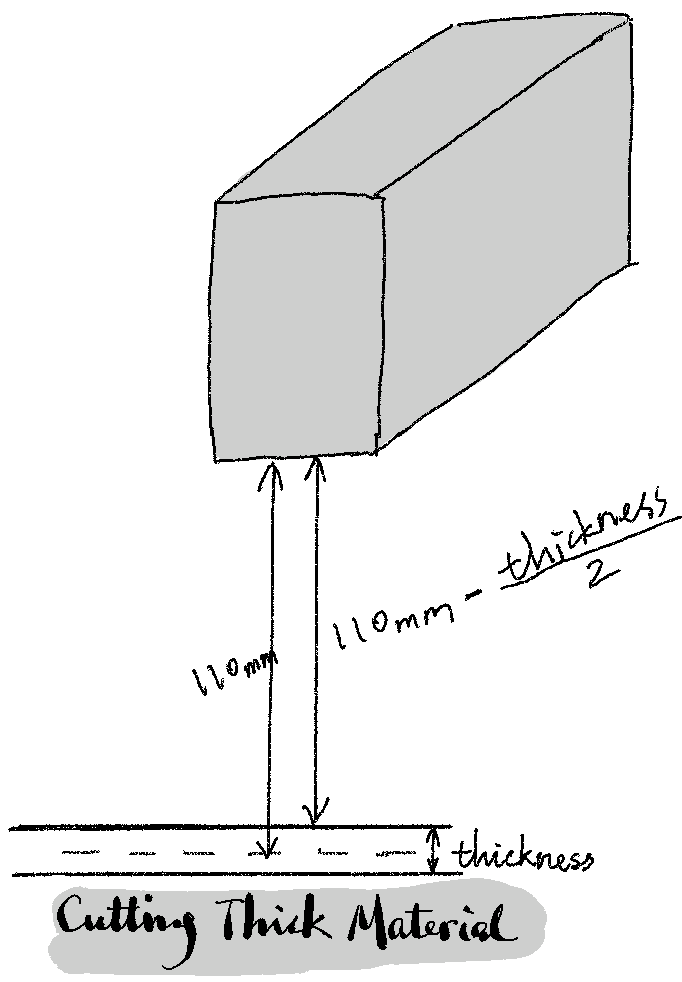

Cutting Thick Material

If you cut sheet material that is more than 3mm thick, it is recommended to set your engraving distance to 110mm - material_thickness/2, so that the perfect 110mm focus point falls in the middle of the material to be cut. In this way, the laser will be out of optimal focus by half material thickness at most. Otherwise, it will be out of focus by 100% material thickness as it cuts through to the bottom side of the material. See the demo of cutting 5.5mm wood in Test #63: Mixed Materials.

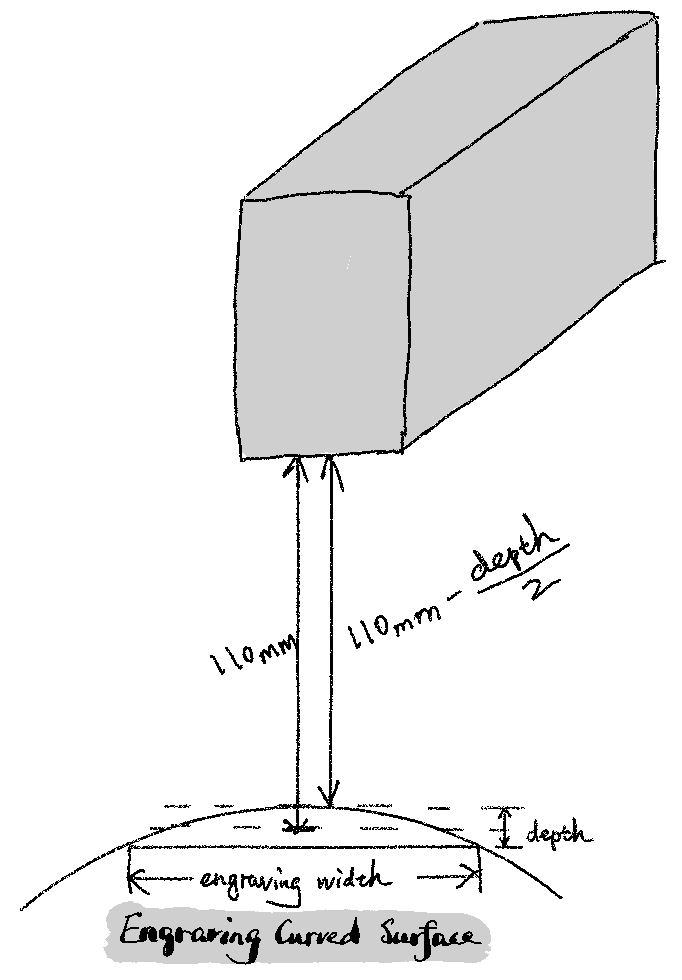

Curved Surface

Because the optimal engraving depth is only 2mm (110±1mm), to minimise the amount the laser becomes out of focus when engraving on a curved surface which has varying distances to the engraver, you should estimate the depth of the engraving area and offset the engraving distance by half of it.

Again, you may want to do some tests to check the engraving quality at slightly different distances before doing the “real job”.

Was this helpful?

4 / 1